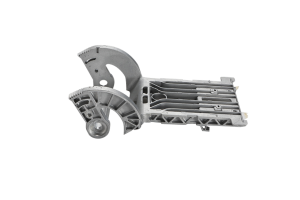

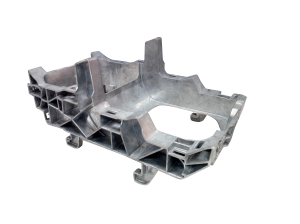

Isisekelo sokusekela i-armrest ye-aluminium cast nge-high pressure die casting

Imininingwane Yomkhiqizo

| Ukucubungula | Ukuphonsa Ngokufa |

| Ukusika | |

| Ukususa ukusha | |

| Ukuqhuma kobuhlalu | |

| Ukupholisha ubuso | |

| Umshini wokugaya i-CNC, ukuthepha, ukujika | |

| Ukususa amafutha | |

| Ukugqoka ngempuphu ngombala omnyama | |

| Ukuhlolwa kosayizi | |

| Imishini | Umshini wokukhipha insimbi kusukela ku-250 ~ 1650tons |

| Imishini ye-CNC enamasethi angu-130 kufaka phakathi uhlobo lwe-Brother kanye ne-LGMazak | |

| Imishini yokubhoboza amasethi angu-6 | |

| Imishini yokuthepha amasethi ama-5 | |

| Umugqa wokususa amafutha ngokuzenzakalelayo | |

| Umugqa wokufaka okuzenzakalelayo | |

| Ukuqina komoya amasethi angu-8 | |

| Umugqa wokumboza ngempuphu | |

| I-Spectrometer (ukuhlaziywa kwezinto zokusetshenziswa) | |

| Umshini wokulinganisa oxhumanisayo (i-CMM) | |

| Umshini we-X-RAY wokuhlola imbobo yomoya noma ukuvuleka kwayo | |

| Isihloli sokuqina | |

| I-Altimeter | |

| Ukuhlolwa kwesifutho sikasawoti | |

| Isicelo | Isisekelo sokukhipha i-aluminium, amakesi emoto, amakesi ebhethri ezimoto zikagesi, izembozo ze-aluminium, izindlu zegiya njll. |

| Ifomethi yefayela esetshenzisiwe | I-Pro/E, i-Auto CAD, i-UG, umsebenzi oqinile |

| Isikhathi esiholayo | Izinsuku ezingama-35-60 zesikhunta, izinsuku eziyi-15-30 zokukhiqiza |

| Imakethe enkulu yokuthumela kwamanye amazwe | INtshonalanga Yurophu, eMpumalanga Yurophu |

| Inzuzo yenkampani | 1) ISO 9001, IATF16949,ISO14000 |

| 2) Ama-workshop okubumba ngodayi kanye nokumboza ngophuphu aphethwe ngabanikazi | |

| 3) Imishini ethuthukisiwe kanye neQembu le-R&D elihle kakhulu | |

| 4) Inqubo yokukhiqiza enekhono eliphezulu | |

| 5) Izinhlobo eziningi zemikhiqizo ye-ODM ne-OEM | |

| 6) Uhlelo Lokulawula Ikhwalithi Eqinile |

Izinqubo Zokukhiqiza Ukuphonsa Ngokufa:

1. Uphenyo- Hlola ukuthi zonke izidingo zicacile -->

2. Isilinganiso esisekelwe kumdwebo we-2D kanye ne-3D-->

3. I-oda Lokuthenga Likhululiwe-->

4. Izinkinga zokuklama nokukhiqiza isikhunta ziqinisekisiwe--->

5. Ukwenza isikhunta-->

6. Ukusampula Ingxenye-->

7. Isampula Evunyiwe-->

8. Ukukhiqizwa ngobuningi --->

9. Ukulethwa kwezingxenye--->

Incazelo ye-DFM ye-ALUMINUM DIE CASTING

I-Design for Manufacturing (DFM) yigama elivame ukusetshenziswa kwezobunjiniyela. Libhekisela enkambisweni yokwenza ngcono ukukhiqiza kube

kwenze kube lula futhi kungabizi ngangokunokwenzeka. I-DFM igxila kakhulu ezindleleni zokukhiqiza kanye nezinqubo ezisetshenziswayo.

Enye yezinzuzo eziyinhloko ze-DFM ukuthi ivumela izinkinga ngendlela yokukhiqiza ukuthi zitholakale futhi zixazululwe kusenesikhathi

esigabeni sokuklama. Kulesi sigaba, izinkinga zishibhile kakhulu ukuzixazulula kunalapho zitholakala ngesikhathi noma ngemva kwalokho.

ukusebenza kokukhiqiza. Ukusebenzisa amasu e-DFM kuvumela ukwehla kwezindleko zokukhiqiza ngenkathi kugcinwa impahla noma

izinga elingcono lekhwalithi.

Ukuze kwenziwe ngcono inqubo yokukhiqiza ama-aluminium die casts, kufanele kuhloswe ngalezi zinhloso ezilandelayo:

1. Sebenzisa inani elincane kakhulu lezinto zokuthunga ngangokunokwenzeka,

2.Qinisekisa ukuthi ingxenye noma umkhiqizo uzophuma kalula edayeni,

3. Nciphisa isikhathi sokuqina sokuphonsa,

4. Nciphisa inani lemisebenzi yesibili ngangokunokwenzeka,

5.Qinisekisa ukuthi umkhiqizo wokugcina uzosebenza njengoba kudingeka.

Umbono wethu wefektri

We have full services except above processing ,we do the surface treatment in house including sandblasting ,chorme plating ,powder coating etc . our goal is to be your preferred partner , welcome to send us the inquiry at info@kingruncastings.com