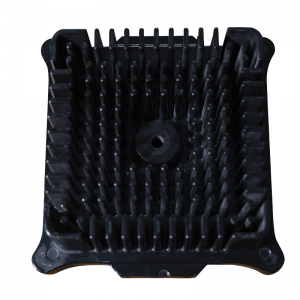

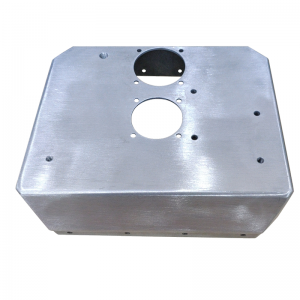

I-heatsink eyenziwe ngokwezifiso ye-Die-cast ye-Radiator

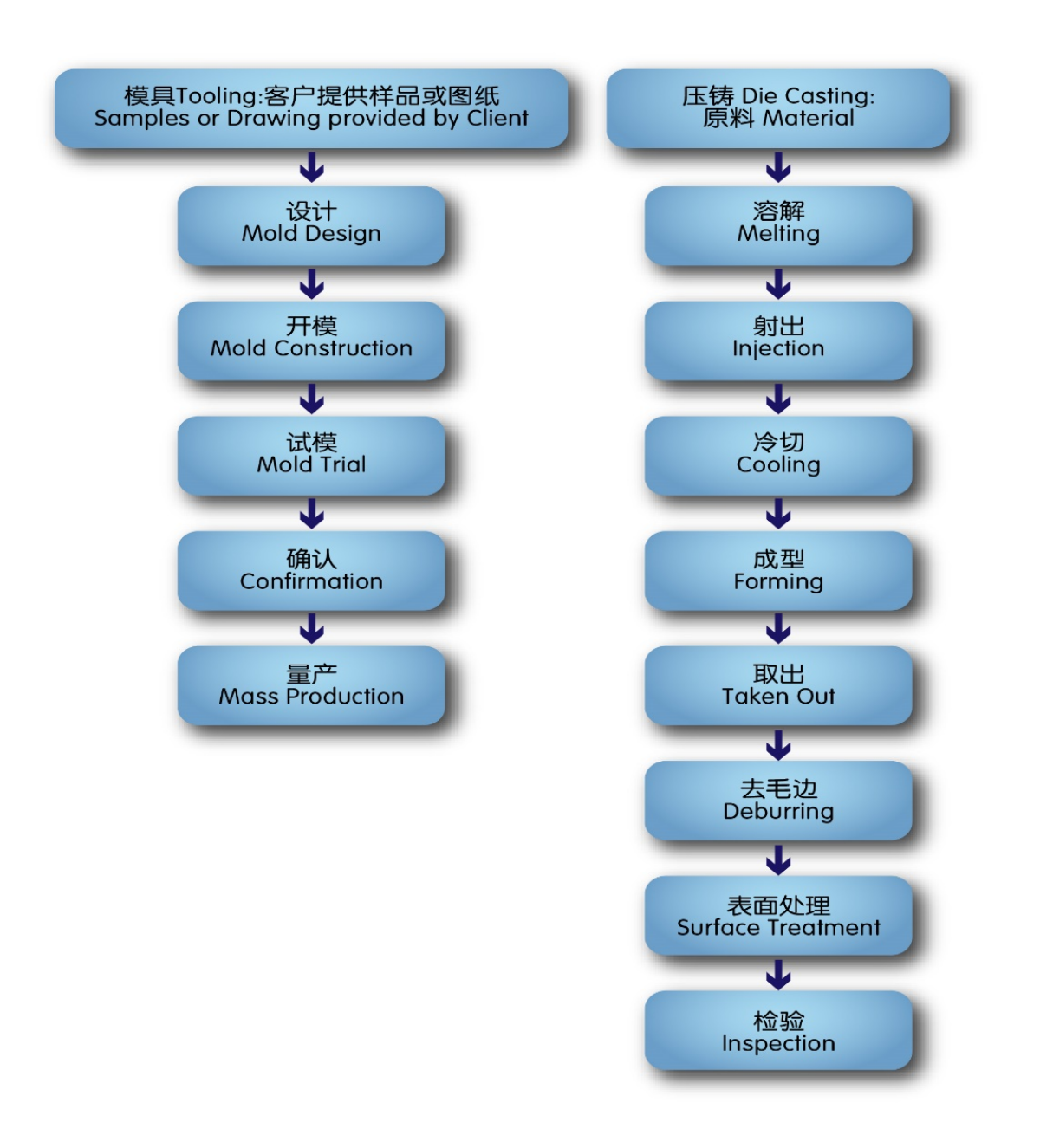

Inqubo yesinki yokushisa

Umklamo wamathuluzi

Ukuphonswa kwe-die okucindezelwe okuphezulu

Ukusika

Ukususa ukusha

Ukuqhuma kwesihlabathi

Ukupholisha ubuso

Ukugqoka Okuyimpuphu

Ukuthepha kanye nokulungisa i-CNC

I-Helical insert

Ukwelashwa Okuphezulu

1. Ukushiswa kwamakhemikhali

2. Ukudweba

3. I-Electrophoresis

4. Ukufaka i-anodizing

5. Ukumbozwa ngempuphu

Izinki zokushisa ezifakwe nge-die cast

Ama-heat sink afakwe i-die cast aphelele uma udinga i-aluminium heat sink eyenzelwe wena. Akhiqizwa ngokuphoqa i-aluminium ewuketshezi ngaphansi kwengcindezi ephezulu ibe yizibunjwa zensimbi. I-die casting heat sink ithandwa emakethe ngoba yenziwe nge-aluminium alloy. Lena yinto ekhethwayo ye-die casting heat sink. Lezi zinqubo ze-die casting zifanelekile ukuhlangabezana nazo zonke izidingo zephrojekthi futhi zenze umkhiqizo osheshayo.

Isikhathi sokuhola esisheshayo kuphela izinsuku ezingama-35-40

Ukusebenza Okuphezulu ekuqedeni kobuso obunomoya

Ubukhulu obuqinile obuphezulu bulawulwa ngaphakathi kwe-+/-0.05mm

Onjiniyela basiza ekuqedeni kusukela ekwakhiweni kuya ekukhiqizeni

Izinzuzo zama-Die Cast Heat Sinks

Uma kuqhathaniswa nezinye izindlela zokukhiqiza, i-die casting inikeza izinzuzo ezilandelayo:

1. Khiqiza izimo eziyinkimbinkimbi ze-3D ezingenakwenzeka ekukhipheni noma ekubumbeni

isinki yokushisa ye-aluminium, uhlaka, indlu, indawo ebiyelwe kanye nezinto zokubopha zingahlanganiswa ekubunjweni okukodwa

2. Ama-Holes angafakwa emigodini ekubunjweni kwedayi

3. Izinga lokukhiqiza eliphezulu kanye nezindleko eziphansi

4. Ukubekezelelana okuqinile

5. Uzinze ngokwezinga

6. Akudingeki imishini yesibili

Nikeza izindawo eziyisicaba kakhulu (ezilungele ukuxhumana phakathi kwesinki yokushisa nomthombo)

Amazinga okumelana nokugqwala kusukela kokuhle kuya kokuphezulu

Ukugeleza kwenqubo yeKingrun

Uma kuqhathaniswa nezinye izindlela zokukhiqiza, i-die casting inikeza izinzuzo ezilandelayo:

1. Khiqiza izimo eziyinkimbinkimbi ze-3D ezingenakwenzeka ekukhipheni noma ekubumbeni

Isinki yokushisa, uhlaka, indlu, indawo ebiyelwe kanye nezinto zokubopha zingahlanganiswa ekubunjweni okukodwa

2. Ama-Holes angafakwa emigodini ekubunjweni kwedayi

3. Izinga lokukhiqiza eliphezulu kanye nezindleko eziphansi

4. Ukubekezelelana okuqinile

5. Uzinze ngokwezinga

6. Akudingeki imishini yesibili

Nikeza izindawo eziyisicaba kakhulu (ezilungele ukuxhumana phakathi kwesinki yokushisa nomthombo)

Amazinga okumelana nokugqwala kusukela kokuhle kuya kokuphezulu

Ukuvikela okuhle kakhulu kwe-EMI ne-RFI