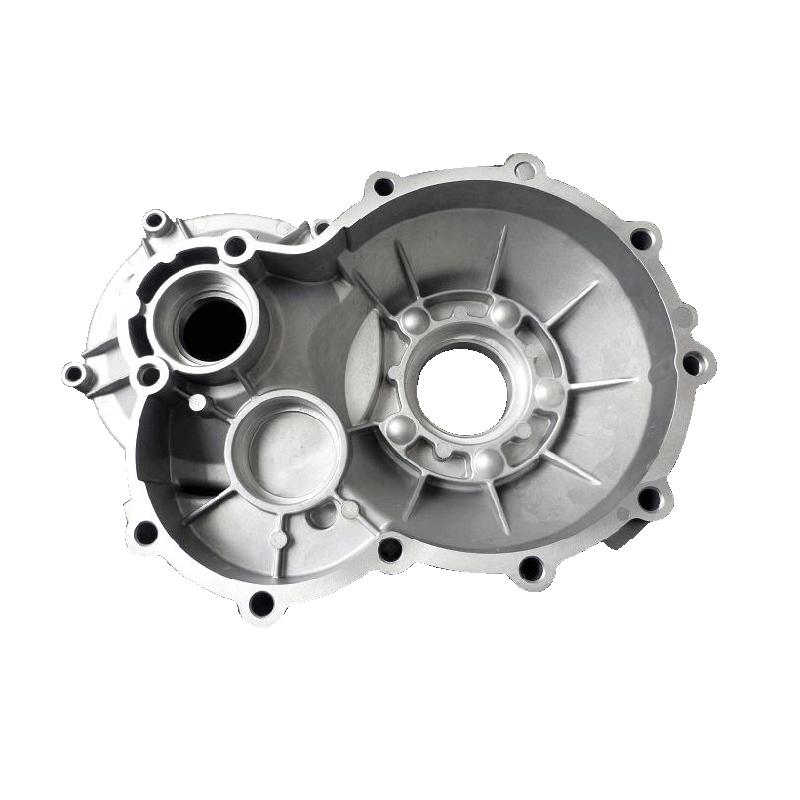

Ukunemba kanye nekhwalithi kubalulekile ekusebenzeni kahle kwezinhlelo ezahlukene zemishini. Ingxenye eyodwa ebalulekile ohlelweni lokudlulisa yi-isembozo sebhokisi legiya lokuphonsa i-aluminiumKule bhulogi, sizohlola inqubo eyinkimbinkimbi yokukhiqiza izingxenye zokubumba ze-aluminium ngokunemba okuphezulu, kusukela ekubumbeni kokuqala kuya ekuqedeni kokugcina.

Ukucindezela Okuphezulu Kokufa:

Ukuze kuqalwe inqubo, kusetshenziswa ukuphonswa kwe-die okunomfutho ophezulu ukuze kulolongwe i-aluminium alloy ibe yisembozo sebhokisi legiya elifunwayo. Le ndlela ihilela ukufaka i-aluminium encibilikisiwe esikhumbeni sensimbi ngaphansi komfutho ophezulu, ukuqinisekisa ukuphindaphindwa okunembile komklamo wesikhunta. Umphumela uba ukuphonswa okuqinile nokunembile okubonisa izakhiwo ezinhle kakhulu zemishini.

Ukusika Nokususa Imfucuza:

Ngemva kwenqubo yokuphonsa, isembozo sebhokisi lamagiya siyanqunywa futhi sisuswe. Ukunquma kuhilela ukususa izinto ezisele ezizungeze imiphetho yokuphonsa ukuze kufezwe ukuma nosayizi ofiselekayo. Ngakolunye uhlangothi, ukususa imiphetho noma ama-burrs aqinile okungenzeka ukuthi akheke ngesikhathi senqubo yokuphonsa. Lezi zinyathelo ezimbili ziphumela esembozweni sebhokisi lamagiya esihlanzekile nesicwengekile esilungele ukuthuthukiswa okwengeziwe.

Ukuqhuma Kwesibhamu:

Ukuqhumisa amashothi kuyisinyathelo esibalulekile enkambisweni yokukhiqiza, njengoba kususa noma yikuphi ukungcola okusele ebusweni bekhava yebhokisi lamagiya. Le ndlela ihilela ukusunduza izinhlayiya ezincane zensimbi ngesivinini esikhulu ebusweni, kususa ngempumelelo noma yikuphi ukungcola, isikali, noma i-oxidation okungase kuthinte ukubukeka kokugcina kanye nokusebenza kwengxenye. Ukuqhumisa amashothi kuqinisekisa indawo ebushelelezi nehlanzekile, elungele isigaba esilandelayo.

Ukupholisha Okungaphezulu:

Ukuze kuthuthukiswe ubuhle nokuqina kwesembozo sebhokisi lamagiya, kusetshenziswa ukupholisha ubuso. Le nqubo ihilela ukugaya nokufutha ubuso kusetshenziswa izinto ezihuquzelayo kanye nezinhlanganisela. Umgomo uwukufeza ukuqeda okufana nesibuko, ukuthuthukisa ukubukeka kanye nokumelana nokugqwala kwengxenye. Ukupholisha ubuso kunikeza isembozo sebhokisi lamagiya ukubukeka kobungcweti nokungaphelele.

Ukuthepha kanye nomshini we-CNC:

Ukuze kuqinisekiswe ukuthi isembozo sebhokisi lamagiya singena kahle ohlelweni lokudlulisa, kwenziwa imishini yokunyathelisa nokuthepha nge-CNC. Umshini wokunyathelisa nge-CNC uhilela ukususa noma yiziphi izinto ezisele kanye nokucwenga ubukhulu obubalulekile ukuze kufezwe izidingo ezifunwayo. Umshini wokunyathelisa uhilela ukudala imicu ekubunjweni okuvumela ukufakwa okulula nokuxhumeka nezinye izingxenye. Lezi zinyathelo ziqinisekisa ukuhambisana nokusebenza kwesembozo sebhokisi lamagiya.

Ukukhiqizwa kweizingxenye zokuphonsa nge-aluminium die ngokunemba okuphezuluuhambo olucophelelayo oluhlanganisa izinqubo ezahlukene zokukhiqiza. Kusukela ekubunjweni kokuqala kuya ezigabeni ezahlukene zokuqeda, njengokusika, ukususa amabhomu, ukuqhumisa ngokudubula, ukupholisha ubuso, ukukhanda nge-CNC, kanye nokuthepha, isinyathelo ngasinye sisiza ekudaleni isembozo sebhokisi lamagiya sekhwalithi ephezulu sezinhlelo zokudlulisa. Ekugcineni, lezi zingxenye zidlala indima ebalulekile ekuqinisekiseni ukusebenza kahle kwezinhlelo zemishini, okubonisa ukubaluleka kobunjiniyela bokunemba ezimbonini zanamuhla.

Isikhathi sokuthunyelwe: Agasti-14-2023