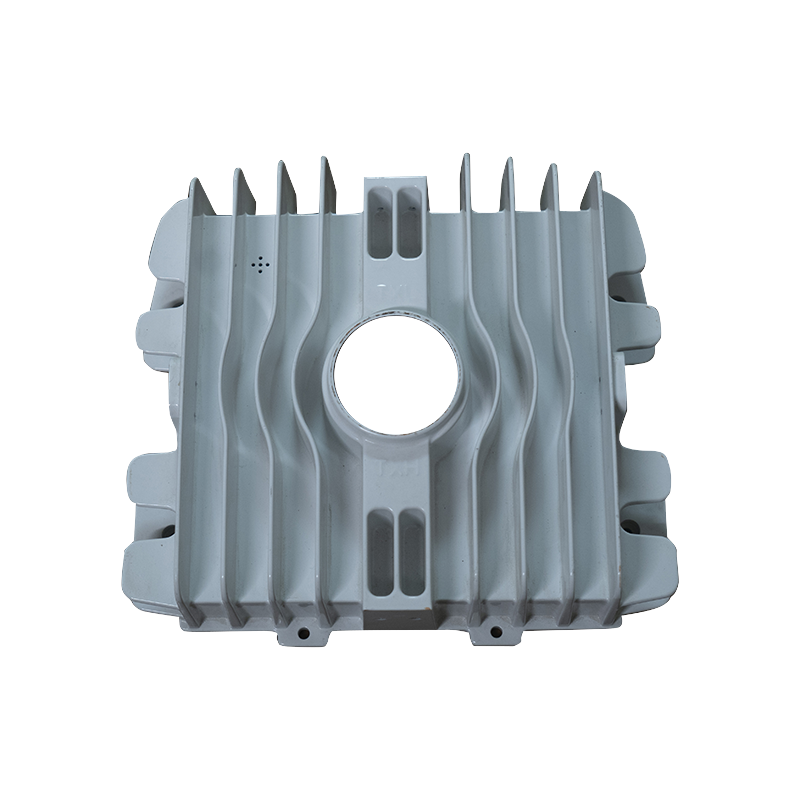

Emkhakheni wemishini yezimboni kanye nobunjiniyela bezimoto, ukubaluleka kwezingxenye ezihlala isikhathi eside eziqinisekisa ukusebenza kahle kakhulu akunakugcizelelwa. Phakathi kwalezi zingxenye,izembozo zokuphonsa i-aluminium alloyziye zavela njengesixazululo esibalulekile nesiguquguqukayo. Ngenxa yamandla azo angavamile, ubunjalo obulula, kanye nezakhiwo ezingagqwali, lezi zimbozo zidlala indima ebalulekile ekuvikeleni imishini ebalulekile nasekuthuthukiseni ukusebenza kwazo konke. Lokhu okuthunyelwe kwebhulogi kuhlolisisa ukubaluleka kwezimbozo zokufaka i-aluminium alloy, kukhanyisa izici zazo ezibalulekile, izinzuzo, kanye nezinhlelo zokusebenza.

1. Ukuvikelwa Okuqinile:

Izimbozo zokubumba ze-aluminium alloy zenzelwe ngqo ukuvikela nokuvikela izingxenye ezibalulekile ezintweni ezahlukahlukene zangaphandle, okuhlanganisa uthuli, imfucumfucu, umswakama, kanye nezimo zezulu ezinzima. Ngokusebenza njengesithiyo sokuvikela, lezi zimbozo zivimbela izinto ezingafuneki ukuthi zingangeni futhi zingalimaza imishini, okunciphisa ingozi yokungasebenzi kahle noma ukuphuka. Ukuqina kwazo kanye nokumelana nomthelela kuqinisekisa isikhathi eside sezingxenye ezimboziwe.

2. Ilula futhi iyasebenziseka:

Uma kuqhathaniswa nezinye izinto ezifana nensimbi noma insimbi, ama-aluminium alloys abonisa izakhiwo ezimangalisayo ezilula, okwenza afaneleke kakhulu ezimbozweni zokuthunga. Isisindo esincishisiwe sinenzuzo ngokuya ngokuthuthwa, ukuphathwa, kanye nokulula kokufakwa. Lolu hlobo olulula lwenza kube nokuguquguquka okukhulu ngenkathi kuklanywa izingxenye eziyinkimbinkimbi, kuqinisekiswa ukulingana okuphelele nokusebenza okuthuthukisiwe. Ngaphezu kwalokho, ama-aluminium alloys angaphonswa ngezindlela ezahlukahlukene, okuvumela ukwenza ngokwezifiso izembozo zokuthunga ngokwezidingo ezithile zemishini.

3. Ukuqhuba Ukushisa:

Esinye isici esizuzisayo sezimbozo zokubumba ze-aluminium alloy ukuqhutshwa kwazo okuhle kakhulu kokushisa. Izimbozo ze-aluminium zinekhono eliphezulu lokuhlakaza ukushisa, elisiza ekuphatheni ngempumelelo ukushisa okukhiqizwa imishini evalekile. Leli khwalithi libaluleke kakhulu ezisetshenziswayo lapho ukulawulwa kwezinga lokushisa kubalulekile ukugcina ukusebenza kahle noma ukuvimbela ukushisa ngokweqile. Ngokuhlakaza ukushisa ngempumelelo, izimbozo zokubumba ze-aluminium alloy zisiza ukwandisa isikhathi sokuphila kwemishini ebucayi futhi zithuthukise ukusebenza kwayo kahle.

4. Ukumelana Nokugqwala:

Ngaphezu kokuqina kwazo, ama-alloy e-aluminium ayaziwa ngokumelana kwawo okungavamile nokugqwala. Lesi sici siwenza afaneleke kakhulu ezimbozweni zokuthunga ezivezwa yizinto ezahlukahlukene zemvelo, njengomswakama, amakhemikhali, noma amanzi anosawoti. Ukumelana nokugqwala akugcini nje ngokuqinisekisa ukuvikelwa kwemishini kodwa futhi kunciphisa izindleko zokulungisa ezihambisana nokulungiswa noma ukushintshwa ngenxa yomonakalo wokugqwala.

5. Uhla Olubanzi Lwezicelo:

Izembozo zokuphonsa i-aluminium alloythola izinhlelo zokusebenza eziningi kuzo zonke izimboni ezahlukene. Zivame ukusetshenziswa ekukhiqizeni izimoto zezimbozo zenjini, ama-gearbox, kanye nezimbozo zokudlulisela. Embonini yezindiza, zisebenza njengezindawo zokuvikela izingxenye ezibalulekile ze-elekthronikhi noma izinhlelo ze-hydraulic. Ngaphezu kwalokho, zisetshenziswa kabanzi ekukhiqizeni imishini esindayo, imishini yokukhiqiza ugesi, ngisho nama-electronics abathengi, ngenxa yemvelo yazo eguquguqukayo kanye nezinzuzo ezinikezayo.

Izimbozo zokubumba i-aluminium alloy sezibe yingxenye ebalulekile yemishini yesimanje ngenxa yezimfanelo zayo ezingenakuqhathaniswa zokuqina, ukwakheka okulula, ukuhanjiswa kokushisa, kanye nokumelana nokugqwala. Lezi zimbozo azivikeli nje kuphela izingxenye ezibalulekile kodwa futhi zithuthukisa ukusebenza futhi ziqinisekise isikhathi eside semishini. Njengoba ubuchwepheshe buthuthuka, kulindeleke ukuthi isidingo sezimbozo zokubumba i-aluminium alloy sikhule, sihlinzekele izimboni ezahlukahlukene ezithembele emishinini eqinile nephumelelayo.

Isikhathi sokuthunyelwe: Novemba-20-2023