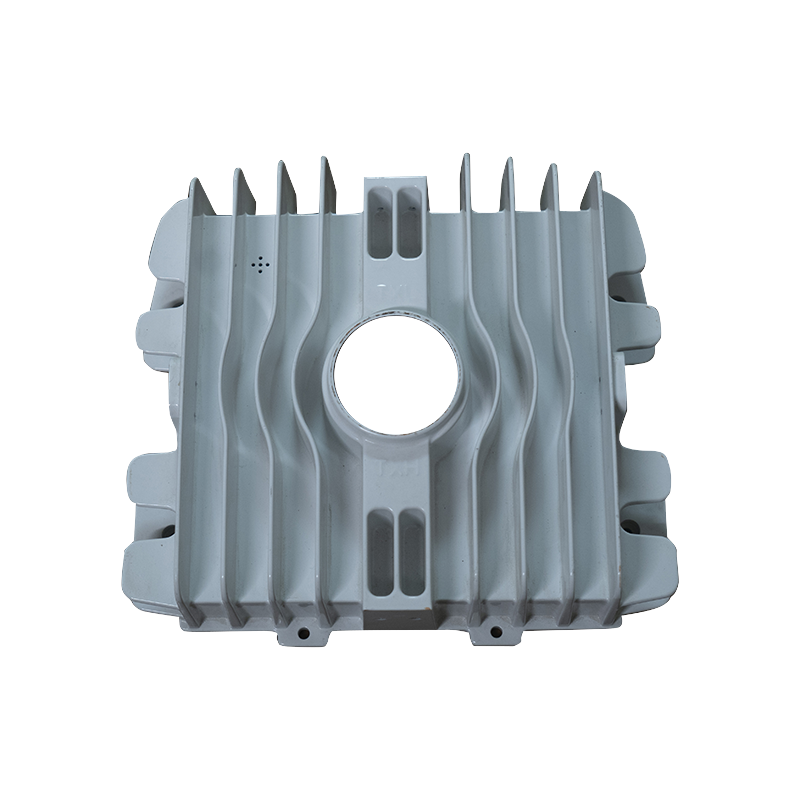

Emkhakheni wemishini yezimboni nobunjiniyela bezimoto, ukubaluleka kwezingxenye ezihlala isikhathi eside eziqinisekisa ukusebenza kahle akukwazi ukugcizelelwa.Phakathi kwalezi zingxenye,i-aluminium alloy casting coverszivele njengesixazululo esibalulekile nesiguquguqukayo.Ngamandla azo akhethekile, imvelo engasindi, kanye nezakhiwo ezimelana nokugqwala, la makhava adlala indima ebalulekile ekuvikeleni imishini ebalulekile nasekuthuthukiseni ukusebenza kwawo kukonke.Lokhu okuthunyelwe kwebhulogi kudingida ukubaluleka kwamakhava e-aluminium alloy casting, okukhanyisa izici zawo ezibalulekile, izinzuzo, kanye nezinhlelo zokusebenza.

1. Ukuvikelwa Okuqinile:

Amakhava e-aluminium alloy aklanyelwe ngokukhethekile ukuvikela nokuvikela izingxenye ezibalulekile ezicini ezihlukahlukene zangaphandle, okuhlanganisa uthuli, udoti, umswakama, nezimo zezulu ezinzima.Ngokusebenza njengesithiyo esivikelayo, lezi zimbozo zivimbela izinto ezingafuneki ukuthi zingangeni futhi ezingase zilimaze emishinini, zinciphisa ubungozi bokungasebenzi kahle noma ukuwohloka.Ukuqina kwazo kanye nokumelana nomthelela kuqinisekisa futhi isikhathi eside sezingxenye ezimboziwe.

2. Ingasindi futhi Iguquguquka:

Uma kuqhathaniswa nezinye izinto ezifana nensimbi noma insimbi, ama-alloys e-aluminium abonisa izakhiwo ezikhangayo ezingasindi, okuwenza alungele ukuphonsa amakhava.Isisindo esincishisiwe sinenzuzo mayelana nokuthutha, ukuphatha, kanye nokulula okuphelele kokufakwa.Le mvelo engasindi yenza kube lula ukuguquguquka ngenkathi iklama izingxenye eziyinkimbinkimbi, iqinisekisa ukulingana okuphelele nokusebenza okuthuthukisiwe.Ngaphezu kwalokho, ama-alloys e-aluminium angajikijelwa emimoyeni ehlukahlukene, okuvumela ukwenziwa ngokwezifiso kwezembozo zokusakaza ezidingweni ezithile zemishini.

3. I-Thermal Conductivity:

Esinye isici esizuzisayo sezembozo ze-aluminium alloy casting yi-conductivity yabo enhle kakhulu yokushisa.Ama-alloys e-aluminium anamandla aphezulu okukhipha ukushisa, esiza ekulawuleni ngempumelelo ukushisa okukhiqizwa imishini evalekile.Le khwalithi ibaluleke kakhulu ezinhlelweni zokusebenza lapho ukulawulwa kwezinga lokushisa kubalulekile ukuze kugcinwe ukusebenza okuphezulu noma ukuvimbela ukushisa ngokweqile.Ngokukhipha ukushisa ngendlela efanele, amakhava okusakaza ingxubevange ye-aluminium asiza ukunweba ubude bempilo bemishini ebucayi futhi athuthukise ukusebenza kahle kwawo kukonke.

4. Ukumelana Nokugqwala:

Ngaphezu kokuqina kwawo, ama-alloys e-aluminium aziwa ngokumelana kwawo okukhethekile nokugqwala.Lesi sakhiwo sibenza bafaneleke kakhulu ukusakaza izembozo ezivezwa izakhi ezahlukahlukene zemvelo, njengomswakama, amakhemikhali, noma amanzi anosawoti.Ukumelana nokugqwala akuqinisekisi ukuvikelwa kwemishini kuphela kodwa futhi kunciphisa izindleko zokuyilungisa ezihambisana nokukhanda noma ukushintshwa ngenxa yokulimala kokugqwala.

5. Uhla Olubanzi Lwezicelo:

Izembozo ze-aluminium alloy castingthola izicelo ezibanzi kuzo zonke izimboni ezahlukene.Avame ukusetshenziswa ekwakhiweni kwezimoto kumakhava enjini, ama-gearbox, namakhava okuhambisa.Embonini ye-aerospace, zisebenza njengezindlu zokuvikela zezingxenye ezibalulekile ze-elekthronikhi noma amasistimu asebenza ngamanzi.Ukwengeza, baqashwe kabanzi ekwenziweni kwemishini esindayo, emishinini yokuphehla ugesi, ngisho nakuma-electronics abathengi, ngenxa yemvelo yabo eguquguqukayo kanye nezinzuzo abazinikezayo.

Izembozo ze-aluminium alloy casting seziyingxenye ebalulekile yemishini yesimanje ngenxa yezimfanelo zazo ezingenakuqhathaniswa zokuqina, umklamo ongasindi, ukuqhutshwa kwe-thermal, nokumelana nokugqwala.Lawa makhava awavikeli nje izingxenye ezibalulekile kuphela kodwa futhi athuthukisa ukusebenza futhi aqinisekise ubude besikhathi semishini.Njengoba ubuchwepheshe buthuthuka, isidingo sezembozo ze-aluminium alloy casting kulindeleke ukuthi sikhule, sihlinzekela izimboni ezahlukahlukene ezithembele emishinini eqinile nesebenza kahle.

Isikhathi sokuthumela: Nov-20-2023